| Availability: | |

|---|---|

| Quantity: | |

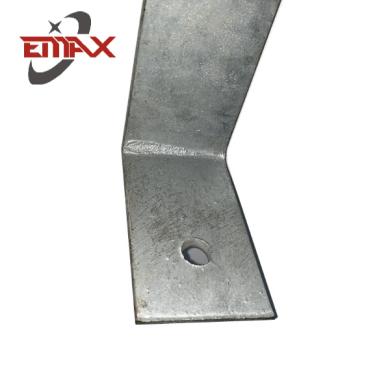

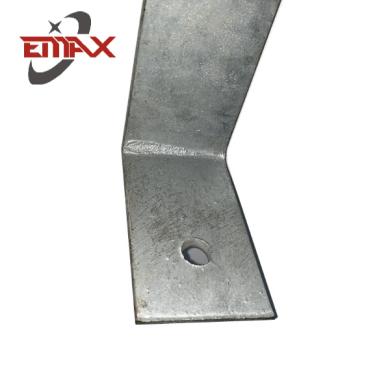

Metal bending parts are one of the most popular choices for building accessories. This type of products function as a connection part, and its quality is the first class with reasonable price, so our company hold confidence in these products to expand the market.

Specification

Product Name: Metal Bending Parts

Surface Treatment: Powder Coated

Material: Q235 steel

Color: OEM customized

Certificate: ISO9001

Enclosure Details

|  |  |

|  |  |

|  |  |

Contact Us

Address: No.393 Fengsheng Industrial Zone, Guali Town, Xiaoshan, Hangzhou, China.

Email: info@emaxmetal.com

Tel: +86-571-83737375

https://www.emaxindustrial.com

Hot Tags: Metal bending parts, China, suppliers, manufacturers, factory, customized, buy, price, bulk, for sale, Welding Steel Bracket, Power Supply Metal Parts, Auto Stamping Parts, Low Voltage Insulator Pins, Communication, War industry, Auto.

Metal bending parts are one of the most popular choices for building accessories. This type of products function as a connection part, and its quality is the first class with reasonable price, so our company hold confidence in these products to expand the market.

Specification

Product Name: Metal Bending Parts

Surface Treatment: Powder Coated

Material: Q235 steel

Color: OEM customized

Certificate: ISO9001

Enclosure Details

|  |  |

|  |  |

|  |  |

Contact Us

Address: No.393 Fengsheng Industrial Zone, Guali Town, Xiaoshan, Hangzhou, China.

Email: info@emaxmetal.com

Tel: +86-571-83737375

https://www.emaxindustrial.com

Hot Tags: Metal bending parts, China, suppliers, manufacturers, factory, customized, buy, price, bulk, for sale, Welding Steel Bracket, Power Supply Metal Parts, Auto Stamping Parts, Low Voltage Insulator Pins, Communication, War industry, Auto.

Metal bending is a crucial process in the manufacturing industry that allows for the creation of various components and structures. By manipulating metal sheets and bars, manufacturers can achieve precise shapes and forms required for different applications. Metal bending parts offer numerous advantages, making them a preferred choice for many industries.

1.Versatility and Flexibility: Metal bending parts provide unparalleled versatility and flexibility in design and functionality. Manufacturers can create complex shapes and structures by bending metal sheets and bars to meet specific requirements. This flexibility allows for the production of customized components that fit perfectly into various applications. From architectural structures to automotive components, metal bending parts can be tailored to suit a wide range of industries.

2.Enhanced Strength and Durability: One of the significant advantages of metal bending parts is the enhanced strength and durability they offer. The bending process increases the structural integrity of the metal, making it more resistant to external forces and impacts. This strength is particularly crucial in applications that require load-bearing capabilities, such as construction and heavy machinery. Metal bending parts can withstand high levels of stress and pressure, ensuring long-lasting performance and reliability.

3.Cost-Effective Production: Metal bending parts offer cost-effective production solutions for manufacturers. The bending process eliminates the need for complex and expensive joining methods like welding or fastening. By bending a single piece of metal, manufacturers can create intricate shapes and structures, reducing the number of components required for assembly. This streamlined production process not only saves time but also reduces material and labor costs, making metal bending parts an economical choice for many industries.

4.Improved Aesthetic Appeal: Metal bending parts can enhance the aesthetic appeal of a product or structure. The ability to create smooth curves and sleek designs through metal bending adds a touch of elegance to the final product. This aesthetic appeal is particularly important in industries such as architecture and interior design, where visual appeal plays a significant role. Metal bending parts offer endless design possibilities, allowing manufacturers to create visually stunning components that stand out from the crowd.

5.Efficient Use of Space: Metal bending parts enable the efficient use of space, especially in applications where compactness is essential. By bending metal sheets and bars, manufacturers can create components that fit perfectly into tight spaces, maximizing the utilization of available areas. This advantage is particularly valuable in industries such as aerospace and electronics, where space constraints are common. Metal bending parts allow for the creation of compact and efficient designs without compromising on functionality or performance.

In conclusion, metal bending parts offer a wide range of advantages that make them indispensable in various industries. The versatility, enhanced strength, cost-effectiveness, improved aesthetic appeal, and efficient use of space make metal bending parts a preferred choice for manufacturers. Whether it is creating complex architectural structures or manufacturing intricate automotive components, metal bending parts provide the necessary flexibility and durability to meet the demands of modern applications.

Metal bending is a crucial process in the manufacturing industry that allows for the creation of various components and structures. By manipulating metal sheets and bars, manufacturers can achieve precise shapes and forms required for different applications. Metal bending parts offer numerous advantages, making them a preferred choice for many industries.

1.Versatility and Flexibility: Metal bending parts provide unparalleled versatility and flexibility in design and functionality. Manufacturers can create complex shapes and structures by bending metal sheets and bars to meet specific requirements. This flexibility allows for the production of customized components that fit perfectly into various applications. From architectural structures to automotive components, metal bending parts can be tailored to suit a wide range of industries.

2.Enhanced Strength and Durability: One of the significant advantages of metal bending parts is the enhanced strength and durability they offer. The bending process increases the structural integrity of the metal, making it more resistant to external forces and impacts. This strength is particularly crucial in applications that require load-bearing capabilities, such as construction and heavy machinery. Metal bending parts can withstand high levels of stress and pressure, ensuring long-lasting performance and reliability.

3.Cost-Effective Production: Metal bending parts offer cost-effective production solutions for manufacturers. The bending process eliminates the need for complex and expensive joining methods like welding or fastening. By bending a single piece of metal, manufacturers can create intricate shapes and structures, reducing the number of components required for assembly. This streamlined production process not only saves time but also reduces material and labor costs, making metal bending parts an economical choice for many industries.

4.Improved Aesthetic Appeal: Metal bending parts can enhance the aesthetic appeal of a product or structure. The ability to create smooth curves and sleek designs through metal bending adds a touch of elegance to the final product. This aesthetic appeal is particularly important in industries such as architecture and interior design, where visual appeal plays a significant role. Metal bending parts offer endless design possibilities, allowing manufacturers to create visually stunning components that stand out from the crowd.

5.Efficient Use of Space: Metal bending parts enable the efficient use of space, especially in applications where compactness is essential. By bending metal sheets and bars, manufacturers can create components that fit perfectly into tight spaces, maximizing the utilization of available areas. This advantage is particularly valuable in industries such as aerospace and electronics, where space constraints are common. Metal bending parts allow for the creation of compact and efficient designs without compromising on functionality or performance.

In conclusion, metal bending parts offer a wide range of advantages that make them indispensable in various industries. The versatility, enhanced strength, cost-effectiveness, improved aesthetic appeal, and efficient use of space make metal bending parts a preferred choice for manufacturers. Whether it is creating complex architectural structures or manufacturing intricate automotive components, metal bending parts provide the necessary flexibility and durability to meet the demands of modern applications.